Table of Contents

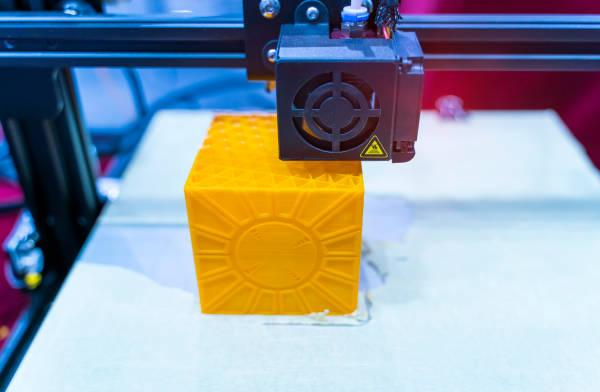

ToggleCompetition in small businesses today is very high; hence, it is very important for a small business to be unique. One of the ways through which this can be attained is by the use of packaging creativity. Welcome 3D printed packaging – a solution with so many benefits for the small business out there. This article aims to shed light on the importance of 3D packaging design and the aspect of custom packaging and how it can put your business a notch higher.

Customization at Its Finest

Small businesses face a lot of difficulties in the market because they cannot compete with larger scales. Thus, 3D printing for the customization of the packaging is one of the most attractive opportunities to develop individual and perfect packaging; as compared to the more conventional techniques that mostly prove limiting and expensive in small-scale production of packages, 3D printing provides infinite flexibility.

For instance, think of a bakery that offers the packaging of macarons in custom boxes. By using 3D printed packaging, they can create boxes that accommodate the macaron, making the product more appealing and, at the same time, providing maximum protection for the macaron during transit.

Cost-Effective Production for 3D Printed Packaging

Expenses are a major factor of consideration among small businesses. Conventional packaging techniques bring in high measures of packaging costs and, in addition, subject them to high minimum orders. Conversely, 3D printing affords mass production even for small runs. This means that you can make only enough packaging units that you require, and this reduces the causality of waste materials as well as storage space.

In the same regard, 3D printing offers minimal or little use for costly molds and tooling that would otherwise be highly necessary in the manufacturing of packaging, according to conventional practices. This makes it convenient for businesses with constantly changing packaging designs or those who need to produce packaging designs for a short time promotion.

Rapid Prototyping and Testing

Based on this rationale, you need to ensure that you evaluate samples and make finality on packaging design before you order your final sets. 3D printing is most useful in prototyping because one is able to produce and test several versions of a packaging design within a brief span and without incurring many costs. This means, you can try out different shapes, sizes and materials of the product without putting a dent on your financial wallet.

To the small businesses, such agility is priceless. It helps you quickly adapt the packaging design based on customers’ suggestions or respond to market conditions. Another element is that, by quickly iterating, you can get the products to market faster than one’s competitors, which is a strong advantage.

Eco-Friendly Solutions

Sustainability is more and more valued from the consumer’s side. The features of 3D printed packaging can allow small businesses to appeal to the focus on environmentally-friendly values. They cited that 3D printing can incorporate biodegradable as well as recyclable materials to decrease the environmental friendlessness of your packaging.

In addition, since 3D printing is accurate, the waste material has been reduced significantly. Typically, in the conventional techniques of manufacturing, there is wastage of materials where surplus material is cooked and then trimmed off and discarded, but in 3D printing, there is no wastage at all as the material required for production of the product only is used. This efficiency is not only advantageous to the community but also assets to the expenses of your material in your business.

Enhanced Functionality

As a result, 3D packaging design appears to have new and unique additional functions that traditional packaging cannot perform. For example, one can make packaging containers with parts or cells for carrying the products, new ways of opening them, or particular shapes that enhance usage. Any such added functionality can help make your product pop out from the competitors’ shelves and be of more value to customers.

Let the business be a small business that deals with the sale of electronics. They can obtain well-suited packaging by using 3D printed packaging in which they can set the definite space for each component to avoid intertwining and damage. Besides increasing the sales appeal of the product, this attention to detail goes a long way in creating trust with the customers as it shows that quality is also being aspired to.

Branding Opportunities

The truth of the matter is that the process of branding plays an important role in establishing customer loyalty, especially for small businesses. In this respect, using custom packaging based on 3D printing opens a great opportunity to strengthen the brand identity. From putting an imprint of your logo on the packaging design to putting shapes that may represent your brand, it is limitless.

As an example, an organization that deals in custom LED signs can appropriately use 3D to produce matching packaging to create a distinctive brand image from the time the client receives the products. Such attention to the technique enhances the branding of small businesses in order to develop synonymous figures with which customers associate.

Innovation and Creativity

To use technology, specifically 3D printing in particular, shows understanding of the current culture and customers’ expectations for innovativeness. Companies that select 3D printed packaging can make them known to consumers as innovative and revolutionary, thus attracting consumers who are individualistic and whose businesses are advanced.

Due to the exclusivity of 3D printing, it is possible to escape from the standards and create unique items that are far from traditional packaging. They give you the ability to test and use geometries, textures and other features that would be challenging when using conventional methods. This creativity can help your products stand out and generate interest in the market, which will get people’s attention and generate sales.

Scalability

Possibly, as in many other aspects, the requirements for the packaging may evolve as your small business develops. Thanks to the advantage of 3D printing, all these changes can be incorporated very easily. Whether there is a need to raise production quantities or change the packaging type, it becomes possible with 3D printing as it does not require long lead times and high costs, as is the case with conventional manufacturing processes.

Such scalability means that your packaging grows with the facet of your business, which in turn makes you capable of responding to new opportunities and slow changes that may manifest themselves on the business frontier. For small businesses, this is a major factor as you would be able to adapt very easily to these factors, and thus offer competition to other more established businesses.

Conclusion

This, therefore, means that 3D-printed packaging will always be of benefit to small businesses. Other areas that demonstrate the advantages of 3D printing for increasing small businesses’ performance include unprecedented opportunities to shape the product in a unique style, achieve cost-efficient production, create prototypes in the shortest time, and use environmentally friendly technologies. On the one hand, incorporating the 3D packaging design and such products as custom packaging will help to stand out from the competitors and improve the circumstances for a customer to buy something, while for your business, it will act as proof of the fact that you and only you are capable of doing it right and becoming a pioneer in the chosen field. In light of this, there are realtor opportunities for 3D printed packaging as the advancement in technology goes higher, creating a competitive advantage for small businesses.